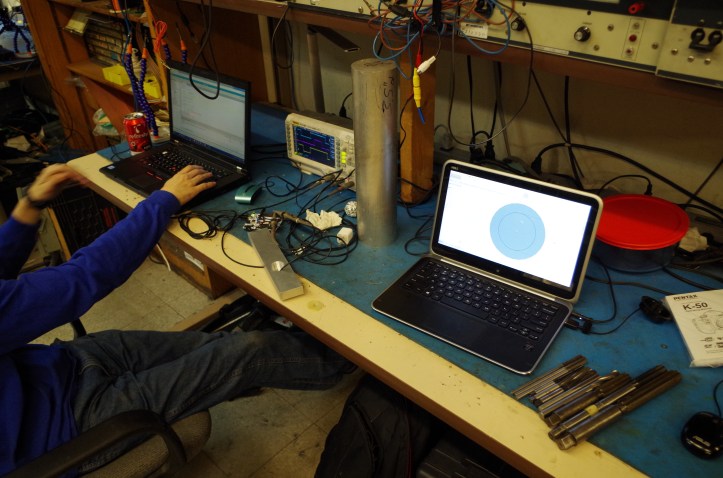

I have wanted to make a combustion engine for quite a while, so I finally decided to build one! I created all the plans myself in Solidworks:

I even looked at what exact reamers were available while I designed, so that I would be able to fabricate my design with the tools available.

Late that night: an engine design was finished! This engine has several unconventional designs, such as a rotary valve, intake and exhaust through the rotating part, and a multi-piece crankshaft.

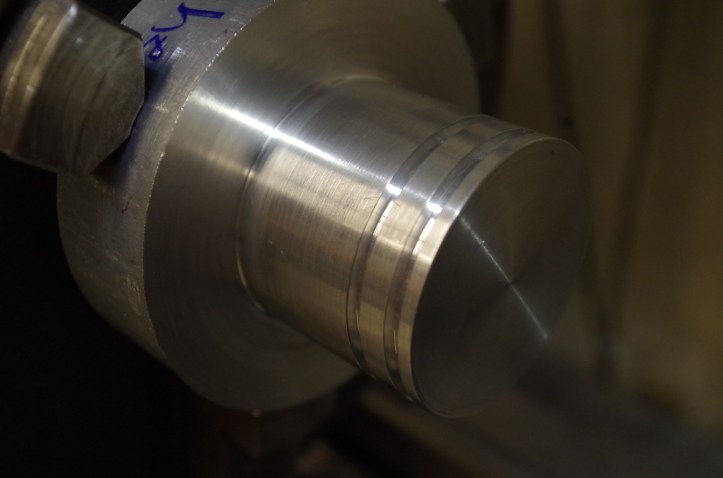

Once the first rough design was finished, I started construction! The most interesting piece to me was the piston, so I grabbed my 3.5inch by 1.5ft aluminum log:

And marked the lengths of a few components:

Then cut on the horizontal bandsaw. Each cut took about 10min.

Notice I’m cutting the head and piston as one block, that way I can grab the head in the lathe while I turn the piston.

I added some cutting oil for emotional support:

The trick is to put a trash can under the saw, so when the part falls, it doesn’t dent.

After about 3 years (10min actual) of cutting:

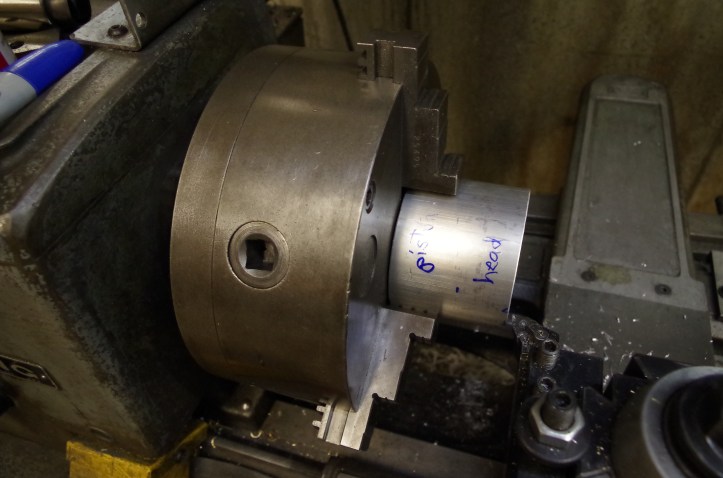

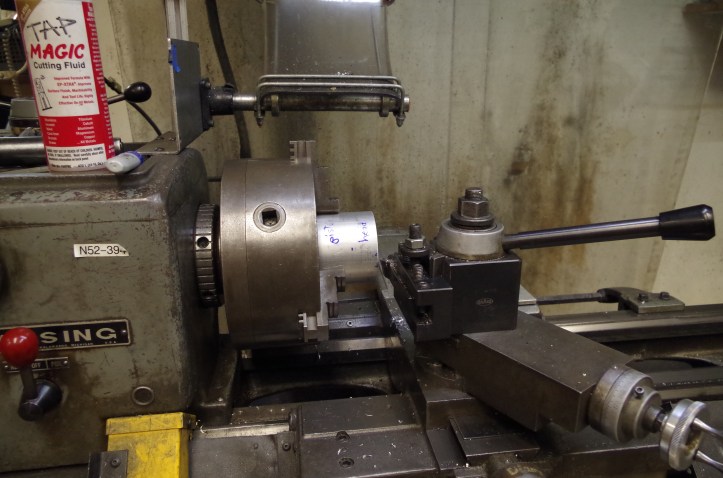

Next, chuck that in the lathe:

Do a quick pass on the end face to make it smooth.

Notice the bandsaw’s cut wasn’t square to begin, so there is an uncut spot on the face. Thankfully, I left lots of extra material for this exact reason.

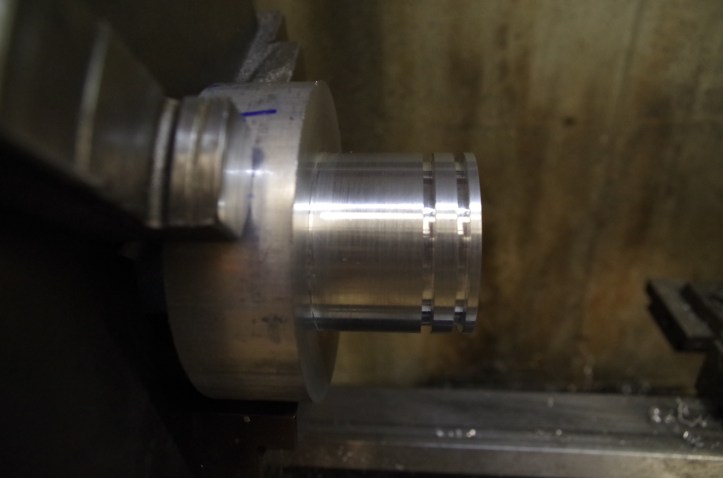

Next, I began turning the piston from the block of metal:

(I took videos, that made tons of data that I need to process. I’ll put them here.)

And at the end, I had a piston plus shavings!

Next up: Cutting the piston off and making the internal features!